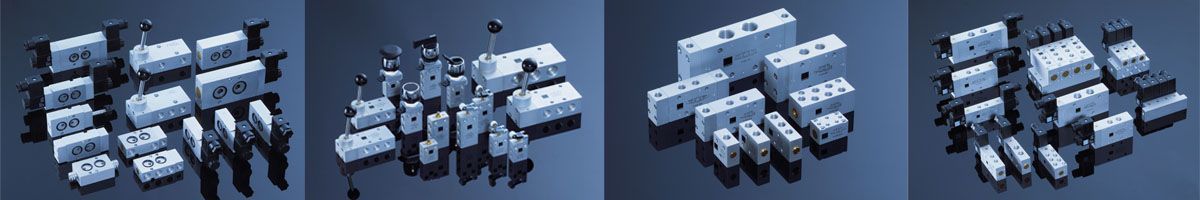

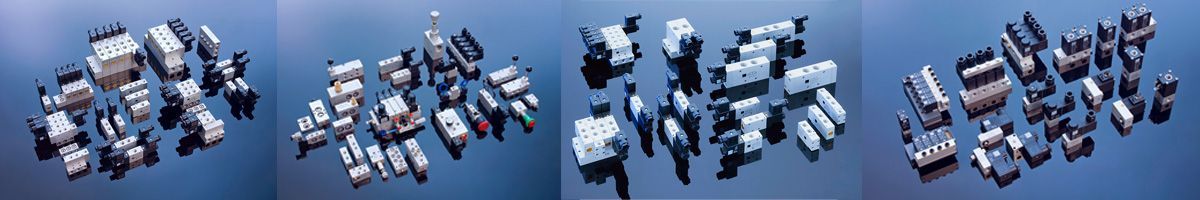

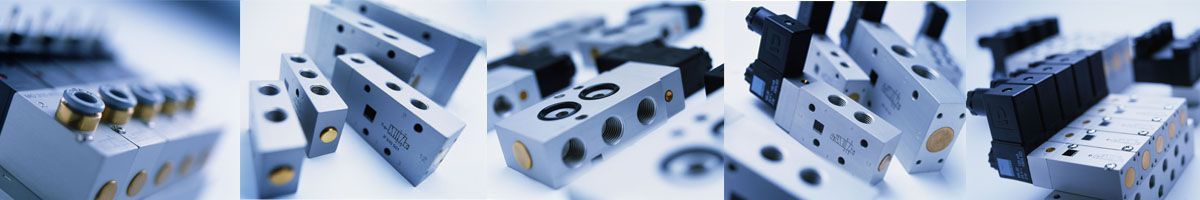

Pneumatics, Compressors, Dryers, Tanks, Pneumatic installations, Air prepration units, Gauges, Pneumatic tubes, Pneumatic valves, Pneumatic cylinders, Pneumatic fittings.

The elements of air preparation, that are neccessary to proper operation of pneumatic installations, are a wide range of products divide into thrree main groups:

ECONOMIC, FUTURA and STANDARD which contain:

- compressed air filters

- compressed air reducers

- compressed air lubricators

- air preparation units

- compressed air Preparation units

- all products are avaliable in sizes G1/8 up to G3”

Compressed air – products overview

1. General information

All elements of the air Preparation system are designed to procced with the requested working medium , that is neccessary to correct operation of the elements of the pneumatic installations. The Preparation of the compressed air is based on:

- purification (filtration) of particles, particles of oil condensate water

- education (regulation) pressure up to the desired operating level

- lubrication with the oil mist.

A properly carried preparation of the compressed air increases the life of pneumatic components, extends the life of the controls and regulations and reduces failure of pneumatic components and systems.

2. The types of working medium’s contaminants

Particulates – entering the pneumatic system of the compressor from the environment or which may arise in the devices of compressed air (compressor), entrained in a stream of flowing medium's quality of parts storage and transporting compressed air. Such particles are released by physico-chemical (corrosion, scale particles, aging and uszkadzanych part seals), or by mechanical as a result of wear of moving parts in the compressor or other pneumatic components contained in the circuit.

Oil - coming our from the compressor (mainly piston’s structure), or in the form of debris entrained by the air flow from the walls of the pipes and equipment. The oil in the form of drops may also be precipitated in the form of condensate in the case of intentional lubrication oil mist pneumatic devices.

Water - in a natural way is dissolved in the form of water vapor in the air aspirated by the compressor atmospheric environment. The amount of water contained in the working medium's quality depends on the air temperature and relative humidity.

3. Methods of compressed air preparation

Purification (filtration) it takes part in fiters, where mainy particualtes are being removed.. They are filtered by the filter cartridges with a specified accuracy of purification. As the standard of cleaning shall be 40 µm, which is equivalent to 5th grade purity of the compressed air and is sufficient for the proper operation of pneumatic fittings. In the case of the use of precision pneumatic components filtration accuracy should be 5 µm at by. ISO 8573-1: 2010 is 3 class air purity. Standard filters also remove precipitated by the expansion of the working medium's quality of water in liquid form. Also removes larger particles of oil that odśrfromkową the whirling force of the spray thrown to the inner surface of tanks. Below is a table of compressed air quality classes.

| Class according to ISO8573-1 |

Max size of particulates | The maximum concentration particulates [mg/m3] |

The maximum value of punktu rosy [°C] |

The maximum concentration of oil [mg/m3] |

The maximum content of H2O [g/m3] |

| I | 0,1 | 0,1 | -70 | 0,01 | 0,003 |

| II | 1 | 1 | -40 | 0,1 | 0,12 |

| III | 5 | 5 | -20 | 1 | 0,88 |

| IV | 15 | 8 | +3 | 5 | 6,0 |

| V | 40 | 10 | +7 | 25 | 7,75 |

| VI | +10 | 9,4 |

Oil removing - the oil contained in the working medium's quality is being removed in the oil-separator maschines. The condensated oil and water may also be removed to some extent in the filters, but it is not a complete removal. The oil-free working medium is particularly important in the selected industries which are food, pharmaceutical, varnishing industry and medicine. It is also not desirable for precision industrial automation.

Drainage of the working medium - preliminary and necessary for the proper operation of the pneumatic components and systems water removal is being done by accurate filters. Removing water from the working medium is required in some applications, and is implemented in dryers that use physical and chemical phenomena (dryers cyclonic, Adsorption dryers, dehumidifiers absorption, refrigeration dryers).

4. Working medium’s pressure regulation

In order to reduce the pressure in the pneumatic installations the pressure regulators are used. They are special valves, that belong to the group of pneumatic elements, that control pressure (usually controlled manually), which mian task is to keep the same working medium’s pressure at the exit, which does not depend on the higher pressure , entrance pressure changes with variable value of flow intensity of medium throght the valve.

5. Compressed air lubrication The lubrication of the compressed air is based on entering the small participles of oil in the form of oil mist , which after reaching to the execution elements, lubricates their moving parts. It prevents failures increases their hardness and reduces the possibility of corrosion. The elements, that produces oil mist are lubricators.

The Design Departament

General Pneumatics

A Reliable company

General trade conditions

ABOUT US

Pomagier-Trzebuchowscy

sp. z o.o.

ul. Marii Skłodowskiej-Curie 97

87-100 Toruń

NIP 556-22-23-819

Regon 092307860

KRS 0000154149

Santander Bank Polska SA

79 10901069 0000 0000 0704 8941

Bank account ING Bank Śląski

64 10501139 1000 0023 4975 0618