Pneumatics, Compressors, Dryers, Tanks, Pneumatic installations, Air prepration units, Gauges, Pneumatic tubes, Pneumatic valves, Pneumatic cylinders, Pneumatic fittings.

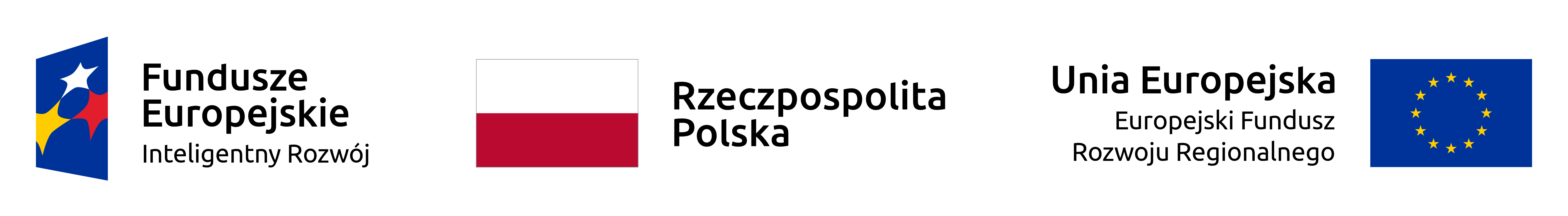

Spool valves - solenoid valves, pneumatic valves, mechanical valves

Spool valves (pneumatic valves) – their task is to control the direction of the working medium’s flow i the drive and control pneumatic systems. The change of the direction of the flow takes part by using the moving slider, spool plate or fungus, it depends on the valve construction.

In the pneumatic control systems they are used to move the executive element (like rotary cylinders).

Their main features are:

- Number of ways of the working medium’s flow,

- Number of location of the flow control element,

- Valve power (Size of the flow intense through the valve ways),

- Type of control,

- Way of feeding the working medium to the control element

Number of working medium’s ways of flow

The spool vales , which you can find in our catalogues:

- 2 - ways,

- 3 - ways,

- 4 - ways,

- 5 - ways

Number of stable location of the flow control element there are:

- 2-ways

- 3-ways

Size of the valve:

The valve size is the size of connection threads which are located on the valve body or sometimes in the connection plaes and manifold plate’s elements, on which such valve can be assembled. The valve size equals the size of flow rate of the working medium through the valve. In pneumatics the most common threads are inch tube’s threads in sizes from G1/8” up to G2”, in case of the very small valves, there are also mteric threads: from M3 up to M6. Any unsual elements of working medium’s controlled flow have threads different, taht those mentioned above.

Types of control:

The type of the control reffers to move of the spool elements, which is responsible for change of the location of theflow ways inside the spool valve. The types of control are given below:

- Solenoid control ( electrical, solenoid valves)

- Pneumatic control ( increase or decrease of the pressure)

- Mechanically control

- Mix

The method of delivery the working medium to the control element.

In pneumatics we speak about spool valves, that are controlled directly or indirectly.

The direct control reffers to small valves and to cut off valves, that are solenoid controlled. It is because of the need of using the electromagnets with high coils power (they produce the force), taht is required to bear the movement resistance and the control’s elements pressure. The advantage of the direct control is fast valves action without the contact of working Medium with internal elemets of elektromagnets. They have also staright construction and there is not neccessery to prepare the air intake chanells.

The indirect control is realized by using the additional, help valve , which is often called „pilot” (controlled in a direct way), which afterr overloading with electric signal or strange pressure puts forward the working medium on to the sufrace of the slider and causes its movement. It is also common to use the additional mechanical control by using the help valve, which allows to overload the valve without giving the electrical signal.The advantage of using the indirect control is the possibility to control the valves with high values of flow intensity with using small solenoid power.

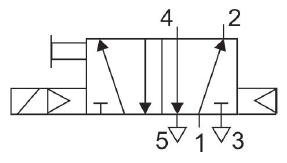

Identification of spool valves basing on the graphic diagram.

In the pneumatic schemes, often the graphic schemes (ful lor simple) of the spool valves are used. Most of them are based on the PN-EN ISO 3952-1:1998.

For example:

Full description:

Spool valve, type MH 510 701, 5-way, 2- road, size G1/4” solenoid control with the voltage 24V DC, own pressure return.

Simple description:

Spool valve MH 510 701 5/2 G1/4 24VDC pressure return,

Graphic scheme:

Markings on the scheme

1 - Working mediun power

2, 4 – receivers

3, 5 – vented receivers

The Design Departament

General Pneumatics

A Reliable company

General trade conditions

ABOUT US

Pomagier-Trzebuchowscy

sp. z o.o.

ul. Marii Skłodowskiej-Curie 97

87-100 Toruń

NIP 556-22-23-819

Regon 092307860

KRS 0000154149

Santander Bank Polska SA

79 10901069 0000 0000 0704 8941

Bank account ING Bank Śląski

64 10501139 1000 0023 4975 0618