Pneumatyka, sprężarki, osuszacze, zbiorniki, instalacje pneumatyczne, stacje przygotowania powietrza, manometry, przewody pneumatyczne, zawory pneumatyczne, siłowniki pneumatyczne, armatura pneumatyczna.

Witamy na stronie firmy HAFNER

Pneumatyka to główna dziedzina działalności firmy HAFNER.

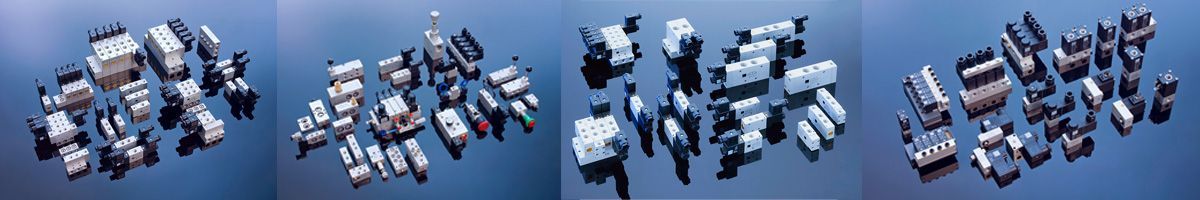

Zajmujemy się kompleksową obsługą Klientów w zakresie dostaw i produkcji elementów pneumatyki siłowej i sterującej. Asortyment obejmuje między innymi sprężarki śrubowe i tłokowe, zbiorniki powietrza, osuszacze i separatory, instalacje pneumatyczne, zawory rozdzielające, odcinające i sterujące, siłowniki pneumatyczne, elementy przygotowania powietrza, chwytaki pneumatyczne, technikę próżniową oraz armaturę pneumatyczną. W ofercie znaleźć można unikatowe rozwiązania elementów dostosowane do specyficznych warunków pracy takich jak niskie temperatury czy środowiska zagrożone wybuchem (Atex, Ex).

W ramach działalności firma produkuje w systemie 24H siłowniki pneumatyczne standardowe i specjalne oraz inne nietypowe elementy pneumatyki. Oferowane i produkowane wyroby odznaczają się wysoką jakością, niezawodnością i trwałością w okresie eksploatacji, co jest potwierdzone stosownymi Certyfikatami. Posiadamy wdrożony System Zarządzania Jakością zgodny z normą ISO 9001:2009.

Wysokie kwalifikacje pracowników i doświadczenie zapewniają profesjonalną i kompleksową obsługę również w zakresie doboru sprężarek, projektowania układów pneumatycznych, doradztwa technicznego i serwisu oraz montażu instalacji pneumatycznych. Utrzymywanie odpowiednich stanów magazynowych pozwala na szybkie realizowanie dostaw dla odbiorców.

Zapraszamy do zapoznania się z krótkim opisem naszej oferty:

Sprężarki

Osuszacze

Zbiorniki

Instalacje pneumatyczne

Filtry i separatory

Stacje przygotowania powietrza

Pomiar ciśnienia i temperatury

Przewody pneumatyczne

Zawory odcinające

Zawory rozdzielające

Zawory sterujące

Siłowniki tłoczyskowe

Siłowniki obrotowe

Chwytaki pneumatyczne

Złącza i akcesoria złączne

Oleje i smary

Narzędzia pneumatyczne

Elementy próżni

DZIAŁ PROJEKTOWY

Podstawy pneumatyki

Rzetelna firma

Ogólne warunki handlowe

O FIRMIE

Pomagier-Trzebuchowscy

sp. z o.o.

ul. Marii Skłodowskiej-Curie 97

87-100 Toruń

NIP 556-22-23-819

Regon 092307860

KRS 0000903675

BDO 000112099

Sąd Rejonowy w Toruniu

VII Wydział Gospodarczy Krajowego Rejestru Sądowego

Kapitał zakładowy: 815.200,00 zł

Konto Santander Bank Polska SA

79 10901069 0000 0000 0704 8941

Konto Bank ING Bank Śląski

64 10501139 1000 0023 4975 0618