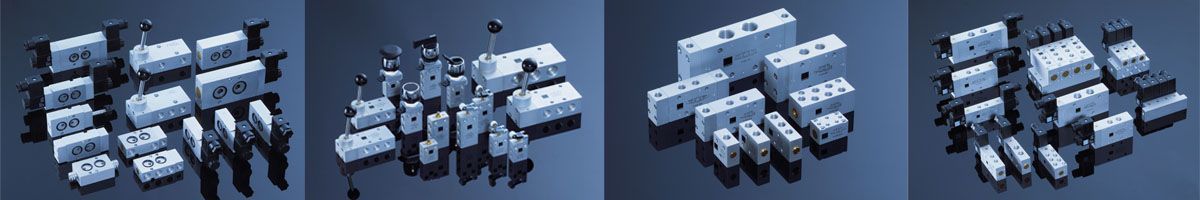

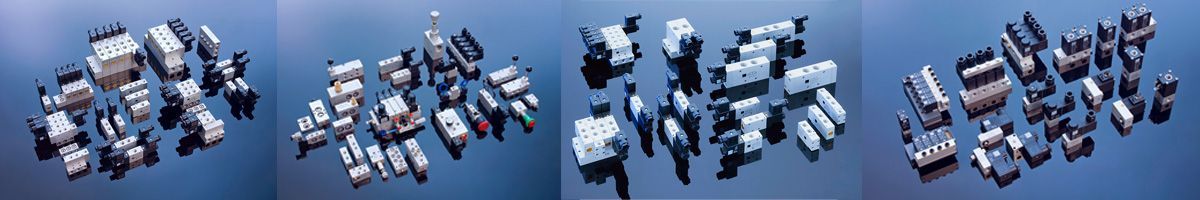

Pneumatics, Compressors, Dryers, Tanks, Pneumatic installations, Air prepration units, Gauges, Pneumatic tubes, Pneumatic valves, Pneumatic cylinders, Pneumatic fittings.

Reciprocating compressor is still the most common type of compressors. The operating element in this case is a piston, which, by performing the reciprocating motion causes suction of gas and in the effect compression. The typical pressure generated by the piston varies from 8 to 10 bars. This type of compressor operates to some extent limit, the rule is the time 50/50. This means that the compressor is not designed for continuous operation. Therefore, reciprocating compressors are very popular, e.g. in tire services and garages.

When selecting a reciprocating compressor, please pay special attention to two main performance values, i.e.:

- Theoretical - this is the amount of air sucked in by the compressor, this value is very often confused with efficient performance, which of course is a mistake!

- Effective performance - this is the amount of compressed air produced by a compressor, it is most important when choosing the value of the compressor..

A very important element, which is the associated to the piston compressor is a tank. Tank’s size affects on the switching frequency of the compressor. The larger the tank is, the longer working time is.

The big advantage of reciprocating compressors is their simple construction and full mobility, by placing a compressor unit on horizontal tank on wheels.

The Design Departament

General Pneumatics

A Reliable company

General trade conditions

ABOUT US

Pomagier-Trzebuchowscy

sp. z o.o.

ul. Marii Skłodowskiej-Curie 97

87-100 Toruń

NIP 556-22-23-819

Regon 092307860

KRS 0000154149

Santander Bank Polska SA

79 10901069 0000 0000 0704 8941

Bank account ING Bank Śląski

64 10501139 1000 0023 4975 0618