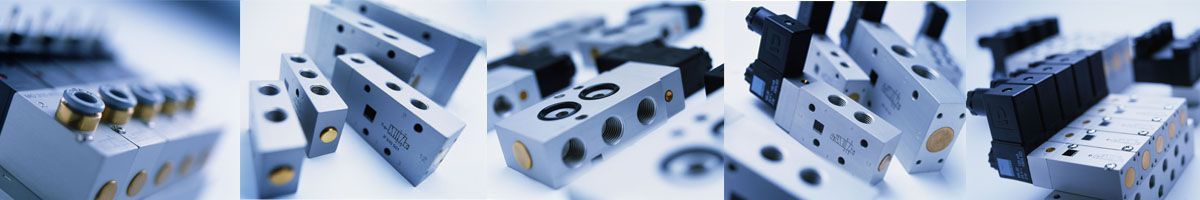

Pneumatics, Compressors, Dryers, Tanks, Pneumatic installations, Air prepration units, Gauges, Pneumatic tubes, Pneumatic valves, Pneumatic cylinders, Pneumatic fittings.

Rotary cylinders ACTUBAR

| Rotary cylinders ACTUBAR |

| Technical data : | ||

| Standard version | Option | |

| Description | - Cylinder with two-side piston from - Type AD - up touble acting - Type AS - single acting(spring return) | |

| Construction features | Technology, pinion mechanism, and a shaft with a self-centering element; single acting: safety springs | |

| Operating position | Any | Any |

| Standards | - The design of the cylinder signaling units: VDI / VDE 3845 (NAMUR) and VDI / VDE 3847 - The design of the cylinder / valve in accordance with NAMUR ie. VDI / VDE 3845 - The design of the cylinder / valve internal thread 4 or 8 cylinders in accordance with EN ISO 5211 | - Alternative mounting and connecting dimensions: a shaft-shaped or up double-D according to DIN ISO 5211 |

| Directives | - ATEX, Machine Guidline | |

| Materials | Tube: aluminium alloy,anodized Covers: Aluminium alloy Piston rfrom / Sprockets: Aluminium alloy Shaft: aluminium alloy Seals: NBR Bearings: selflubricating polimer Screws: stainless steelA2 | Tube: anodized, powder, SILACOAT® Covers: SILACOAT® Shaft: stainless steel AISI 303; AISI 316 on request |

| Ambient temp. | from -20°C up to +80°C | - Designed to operate in low working temperatures : from -40°C up to 80°C - Designed to operate in high working temperatures from 20°C up to 160°C |

| Pivoting angle | - Double and single acting: 90° - Adjustable swivel, standard angles from +5° up to -10° w obu pozycjach | |

| Torque | from 2.5 up to 6000 Nm | |

| Pressure | from 2 up to 8 bar | |

| Medium’s quality | Filtered air with the minimal oil residue, dust according to Class 4 DIN ISO 8573-1 | Special version - other non-corrosive gases or liquids |

| Catalogue number creation | |||||||||

| Double acting |

|

||||||||

| Single acting |

|

||||||||

| 1. Function: | |||||||||

| - AD - Rotary cylinders double side; | |||||||||

| 2. Size: | |||||||||

| Size according to the diagrams. | |||||||||

| 3. Pivoting angle: | |||||||||

| 90° | |||||||||

| 4. Number of springs: | |||||||||

| For example. 08 – eight springs | |||||||||

| 5. Shaft type: | |||||||||

| - V - octagonal - Z - double„D” | |||||||||

| 6. Mounting type | |||||||||

| Different mounting types. All details are given in the technical data sheet. |

The Design Departament

General Pneumatics

A Reliable company

General trade conditions

ABOUT US

HAFNER

Pomagier-Trzebuchowscy

sp. z o.o.

ul. Marii Skłodowskiej-Curie 97

87-100 Toruń

Pomagier-Trzebuchowscy

sp. z o.o.

ul. Marii Skłodowskiej-Curie 97

87-100 Toruń

NIP 556-22-23-819

Regon 092307860

KRS 0000154149

Santander Bank Polska SA

79 10901069 0000 0000 0704 8941

Bank account ING Bank Śląski

64 10501139 1000 0023 4975 0618